Zinc Plated Fasteners

Coated Fasteners

Zinc Plated Fasteners, Stainless Steel 304 Zinc Plated Bolts, Zinc Plated Studs, SS 310 Zinc Plated Stud Bolts, Zinc Plated Threaded Rods, SS 316 Zinc Plated Threaded Bars, Zinc Plated Nuts Manufacturer in Mumbai, India.

Zinc plating and electro-etching are both electro-proof forms; therefore, they are indistinguishable from one another at their most fundamental level. Zinc plating, as opposed to sheet metal, is typically used for finishing small items such as screws, wrench handles, springs, as well as other components. As a disposable zinc terminal, either a cyanide, an antacid that does not include cyanide, or a corrosive chloride salt is supplied to the system. Cyanide showers are the most effective method, despite the fact that they are harmful to the environment and can contribute to pollution.

After the components have been cleaned with a solvent or electrolyte, pickled, and flushed to remove surface oxides, the components are stacked in barrels, racks, or drums before being submerged in a plating system. May add different lighting operators to the solution to increase brightness, but careful management is required to provide a high-quality item. Post-plating medicines can be utilised to passivate the zinc surface, resulting in a different transparent hue or an extension of the coating’s service life. Zinc plating is a process frequently utilised for fasteners such as screws and other small latches, light switch plates, and a variety of other small parts that are subjected to interior environments or fairly harmful situations. Extra protection against corrosion is provided by a chromate-change coating, which must be applied to the material before it can be used in situations that are moderate or severe.

About Zinc Plated Fasteners

The rust or surface scales are removed from the metal by cleaning the surface with a fundamental cleaner and then treating it with a corrosive. When electroplating zinc, cleanliness is essential because oil molecules can stop the coating from layering or corroding if they come into contact with it.

The metal is then submerged in a synthetic shower filled with fragments of zinc before the following step of the process, which is the deposition of zinc onto the metal. Zinc is then placed on the cathode due to the application of a direct current. Finished items, particularly those with recesses, sometimes use soluble zinc showers to achieve a consistent zinc thickness progressively.

Because there is less corrosion of the zinc that has been deposited, this results in a more extended guarantee period from the point of consumption. A zinc coating can significantly extend the time needed for a white rust system to form. Sealants, presently often recommended by the automotive industry, are applied to finished items as well, further extending the erosion protection they provide.

Specification of Zinc Plated Fasteners

| Specifications | IS, ANSI, ASTM DIN, ISO, JIS, GB, ASME, BS, UNI and all International Standards |

| Threads | BSF, UNF METRIC, UNC, BSW or as required |

| Standard | M02 to M33ANSI – American National Standards Institute SS Stud Bolt length are defined in ASME B16.5 standard ANSI B 28.2.4 1M ANSI B 18.2.4 2M ASME B18.5 SS Hex nuts are defined in ASME B18.2.2 DIN: DIN 933, DIN 931, DIN 970, DIN 934 UTS – Unified Thread Standard : UNF, NPT, NPTF, UNS, UNC, UNEF ISO – International Organization for Standardization ISO 4033, : ISO 4032, JIS standards |

| Fasteners/ Bolts Size | M10, M4, M16, M36 M2.5, M6, M30, M12, M8, M14, M2, M3, M20, M24, M5 to M160 |

| Length | 3 mm to 200 mm |

| Head drive | Phillips, Slotted, Phillips/Slot, Six-Lobe etc |

| Test Certificate | as per EN 10204 / 3.1 Manufacturer Test Certificate |

| Finishing | Zinc white, (yellow, black, blue), black oxide, Dacroment, Geometry, plated zinc-nickel, anodizing, nickel plated, Stainless steel: Passivated Self-Colour, Bright Zinc Plated (BZP), Hot Dip Galvanised (HDG), Sherardized, Stainless Steel, some special one like DACROMET and Mechanically Applied coating |

| raw materials of Source | JSPL, Usha Martin, Tata Steel, Mukund Steel, RINL, Dhamm Steel etc. |

| Surface Coating | Zinc Plated Fasteners |

| Packing | IN BULK: pallet, canton, carton / Small Boxs / pallet or customer request |

Dimensions Of Zinc Plated Fasteners

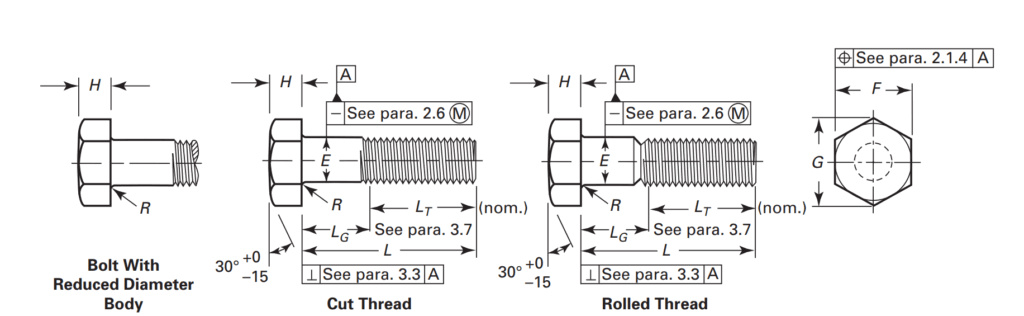

Zinc Plated Bolts Dimensions Chart :

| Nominal Size or Basic Product Diameter | Full-Size Body Diameter, E | Width Across Flats, F | Width Across Corners, G | Head Height, H Basic | Radius of Fillet, R | Nominal Thread Length for Bolt Lengths, LT |

|||||||||

| inch | mm | Max | Min | Basic inch | Max | Min | Max | Min | Basic inch | Max | Min | Max | Min | 6 in. and Shoter | Over 6 in. |

| 1⁄4 | 0.25 | 0.26 | 0.237 | 7⁄16 | 0.438 | 0.425 | 0.505 | 0.484 | 11⁄64 | 0.188 | 0.15 | 0.03 | 0.01 | 0.75 | 1 |

| 5⁄16 | 0.3125 | 0.324 | 0.298 | 1⁄2 | 0.5 | 0.484 | 0.577 | 0.552 | 7⁄32 | 0.235 | 0.195 | 0.03 | 0.01 | 0.875 | 1.125 |

| 3⁄8 | 0.375 | 0.388 | 0.36 | 9⁄16 | 0.562 | 0.544 | 0.65 | 0.62 | 1⁄4 | 0.268 | 0.226 | 0.03 | 0.01 | 1 | 1.25 |

| 7⁄16 | 0.4375 | 0.452 | 0.421 | 5⁄8 | 0.625 | 0.603 | 0.722 | 0.687 | 19⁄64 | 0.316 | 0.272 | 0.03 | 0.01 | 1.125 | 1.375 |

| 1⁄2 | 0.5 | 0.515 | 0.482 | 3⁄4 | 0.75 | 0.725 | 0.866 | 0.826 | 11⁄32 | 0.364 | 0.302 | 0.03 | 0.01 | 1.25 | 1.5 |

| 5⁄8 | 0.625 | 0.642 | 0.605 | 15⁄16 | 0.938 | 0.906 | 1.083 | 1.033 | 27⁄64 | 0.444 | 0.378 | 0.06 | 0.02 | 1.5 | 1.75 |

| 3⁄4 | 0.75 | 0.768 | 0.729 | 11⁄8 | 1.125 | 1.088 | 1.299 | 1.24 | 1⁄2 | 0.524 | 0.455 | 0.06 | 0.02 | 1.75 | 2 |

| 7⁄8 | 0.875 | 0.895 | 0.852 | 1 5⁄16 | 1.312 | 1.269 | 1.516 | 1.447 | 37⁄64 | 0.604 | 0.531 | 0.06 | 0.02 | 2 | 2.25 |

| 1 | 1 | 1.022 | 0.976 | 1 1⁄2 | 1.5 | 1.45 | 1.732 | 1.653 | 43⁄64 | 0.7 | 0.591 | 0.09 | 0.03 | 2.25 | 2.5 |

| 1 1⁄8 | 1.125 | 1.149 | 1.098 | 1 11⁄16 | 1.688 | 1.631 | 1.949 | 1.859 | 3⁄4 | 0.78 | 0.658 | 0.09 | 0.03 | 2.5 | 2.75 |

| 1 1⁄4 | 1.25 | 1.277 | 1.223 | 1 7⁄8 | 1.875 | 1.812 | 2.165 | 2.066 | 27⁄32 | 0.876 | 0.749 | 0.09 | 0.03 | 2.75 | 3 |

| 1 3⁄8 | 1.375 | 1.404 | 1.345 | 2 1⁄16 | 2.062 | 1.994 | 2.382 | 2.273 | 29⁄32 | 0.94 | 0.81 | 0.09 | 0.03 | 3 | 3.25 |

| 1 1⁄2 | 1.5 | 1.531 | 1.47 | 2 1⁄4 | 2.25 | 2.175 | 2.598 | 2.48 | 1 | 1.036 | 0.902 | 0.09 | 0.03 | 3.25 | 3.5 |

| 1 5⁄8 | 1.625 | 1.658 | 1.591 | 2 7⁄16 | 2.438 | 2.356 | 2.815 | 2.616 | 1 3⁄32 | 1.116 | 0.978 | 0.09 | 0.03 | 3.5 | 3.75 |

| 1 3⁄4 | 1.75 | 1.785 | 1.716 | 2 5⁄8 | 2.625 | 2.538 | 3.031 | 2.893 | 1 5⁄32 | 1.196 | 1.054 | 0.12 | 0.04 | 3.75 | 4 |

| 1 7⁄8 | 1.875 | 1.912 | 1.839 | 2 13⁄16 | 2.812 | 2.719 | 3.248 | 3.099 | 1 1⁄4 | 1.276 | 1.13 | 0.12 | 0.04 | 4 | 4.25 |

| 2 | 2 | 2.039 | 1.964 | 3 | 3 | 2.9 | 3.464 | 3.306 | 1 11⁄32 | 1.388 | 1.175 | 0.12 | 0.04 | 4.25 | 4.5 |

| 2 1⁄4 | 2.25 | 2.305 | 2.214 | 3 3⁄8 | 3.375 | 3.262 | 3.897 | 3.719 | 1 1⁄2 | 1.548 | 1.327 | 0.19 | 0.06 | 4.75 | 5 |

| 2 1⁄2 | 2.5 | 2.559 | 2.461 | 3 3⁄4 | 3.75 | 3.625 | 4.33 | 4.133 | 1 21⁄32 | 1.708 | 1.479 | 0.19 | 0.06 | 5.25 | 5.5 |

| 2 3⁄4 | 2.75 | 2.827 | 2.711 | 4 1⁄8 | 4.125 | 3.988 | 4.763 | 4.546 | 1 13⁄16 | 1.869 | 1.632 | 0.19 | 0.06 | 5.75 | 6 |

| 3 | 3 | 3.081 | 2.961 | 4 1⁄2 | 4.5 | 4.35 | 5.196 | 4.959 | 2 | 2.06 | 1.815 | 0.19 | 0.06 | 6.25 | 6.5 |

| 3 1⁄4 | 3.25 | 3.335 | 3.21 | 4 7⁄8 | 4.875 | 4.712 | 5.629 | 5.372 | 2 3⁄16 | 2.251 | 1.936 | 0.19 | 0.06 | 6.75 | 7 |

| 3 1⁄2 | 3.5 | 3.589 | 3.461 | 5 1⁄4 | 5.25 | 5.075 | 6.062 | 5.786 | 2 5⁄16 | 2.38 | 2.057 | 0.19 | 0.06 | 7.25 | 7.5 |

| 3 3⁄4 | 3.75 | 3.858 | 3.726 | 5 5⁄8 | 5.625 | 5.437 | 6.495 | 6.198 | 2 1⁄2 | 2.572 | 2.241 | 0.19 | 0.06 | 7.75 | 8 |

| 4 | 4 | 4.111 | 3.975 | 6 | 6 | 5.8 | 6.928 | 6.612 | 2 11⁄16 | 2.764 | 2.424 | 0.19 | 0.06 | 8.25 | 8.5 |

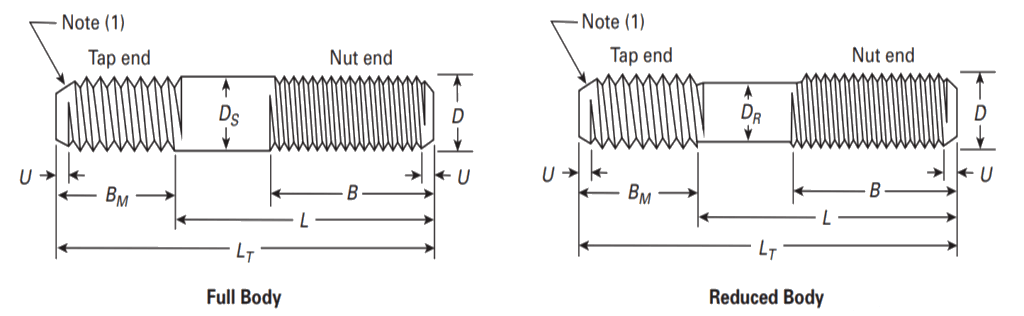

Zinc Plated Stud Bolts Dimensions Chart :

| Nominal Size Diameter, D inch | Tap End Full Thread Length, BM | Umax = 2P | Minimum Nut End Full Thread Length, Bmin |

||||||

| Nominal | Min. | Max. | UNC & NC-5 Thread | UNF Thread | 8UN Thread | L ≤ 10 | 10 | L > 16 | |

| 1/4 | 0.375 | 0.350 | 0.400 | 0.100 | 0.071 | ... | 0.750 | 1.000 | 1.500 |

| 5/16 | 0.469 | 0.440 | 0.498 | 0.111 | 0.083 | -- | 0.875 | 1.125 | 1.625 |

| 3/8 | 0.563 | 0.532 | 0.594 | 0.125 | 0.083 | -- | 1.000 | 1.250 | 1.750 |

| 7/16 | 0.656 | 0.620 | 0.692 | 0.143 | 0.100 | -- | 1.125 | 1.375 | 1.875 |

| 1/2 | 0.750 | 0.708 | 0.792 | 0.154 | 0.100 | -- | 1.250 | 1.500 | 2.000 |

| 9/16 | 0.844 | 0.802 | 0.896 | 0.167 | 0.111 | -- | 1.375 | 1.625 | 2.125 |

| 5/8 | 0.938 | 0.892 | 0.983 | 0.182 | 0.111 | -- | 1.500 | 1.750 | 2.250 |

| 3/4 | 1.1.25 | 1.075 | 1.175 | 0.200 | 0.125 | -- | 1.750 | 2.000 | 2.500 |

| 7/8 | 1.313 | 1.258 | 1.368 | 0.222 | 0.143 | -- | 2.000 | 2.250 | 2.750 |

| 1 | 1.500 | 1.438 | 1.562 | 0.250 | 0.167 | -- | 2.250 | 2.500 | 3.000 |

| 1 1/8 | 1.688 | 1.625 | 1.750 | 0.286 | 0.167 | 0.250 | 2.500 | 2.750 | 3.250 |

| 1 1/4 | 1.875 | 1.813 | 1.938 | 0.286 | 0.167 | 0.250 | 2.750 | 3.000 | 3.500 |

| 1 3/8 | 2.063 | 2.000 | 2.125 | 0.333 | 0.167 | 0.250 | 3.000 | 3.250 | 3.750 |

| 1 1/2 | 2.250 | 2.188 | 2.313 | 0.333 | 0.167 | 0.250 | 3.250 | 3.500 | 4.000 |

| 1 5/8 | 2.438 | 2.375 | 2.500 | -- | -- | 0.250 | 3.500 | 3.750 | 4.250 |

| 1 3/4 | 2.625 | 2.563 | 2.688 | 0.400 | -- | 0.250 | 3.750 | 4.000 | 4.500 |

| 1 7/8 | 2.813 | 2.750 | 2.875 | -- | -- | 0.250 | 4.000 | 4.250 | 4.750 |

| 2 | 3.000 | 2.925 | 3.075 | 0.444 | -- | 0.250 | 4.250 | 4.500 | 5.000 |

| 2 1/4 | 3.375 | 3.300 | 3.450 | 0.444 | -- | 0.250 | 4.750 | 5.000 | 5.500 |

| 2 1/2 | 3.750 | 3.675 | 3.825 | 0.500 | -- | 0.250 | 5.250 | 5.500 | 6.000 |

| 2 3/4 | 4.125 | 4.050 | 4.200 | 0.500 | -- | 0.250 | 5.750 | 6.000 | 6.500 |

| 3 | 4.500 | 4.425 | 4.575 | 0.500 | -- | 0.250 | -- | 6.500 | 7.000 |

| 3 1/4 | 4.875 | 4.775 | 4.975 | 0.500 | -- | 0.250 | -- | 7.000 | 7.500 |

| 3 1/2 | 5.250 | 5.150 | 5.350 | 0.500 | -- | 0.250 | -- | 7.500 | 8.000 |

| 3 3/4 | 5.625 | 5.525 | 5.725 | 0.500 | -- | 0.250 | -- | 8.000 | 8.500 |

| 4 | 6.000 | 5.900 | 6.100 | 0.500 | -- | 0.250 | -- | 8.500 | 9.000 |

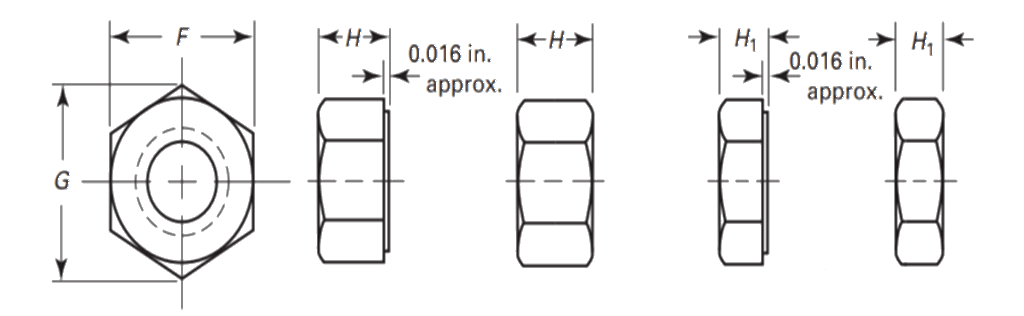

Zinc Plated Nuts Dimensions :

| Nominal Size inch | Basic Major Diameter of Thread | Width Across Flats, F | Width Across Corners, G | Thickness Heavy Hex Nuts, H | Thickness Heavy Hex Jam Nuts, H1 | Maximum Runout of Bearing Surface to Thread Axis, FIM |

|||||||||

| Heavy HEX NUTS | Heavy Hex Jam Nuts |

||||||||||||||

| Specified Proof load | |||||||||||||||

| Basic inch | Min. | Max | Min. | Max | Basic inch | Min. | Max | Basic inch | Min. | Max | Up to 150,000 psi | 150,000 psi and Greater | All Strength Levels |

||

| 1/4 | 0.2500 | 1/2 | 0.488 | 0.500 | 0.556 | 0.577 | 15/64 | 0.218 | 0.250 | 11/64 | 0.156 | 0.188 | 0.017 | 0.011 | 0.017 |

| 5/16 | 0.3125 | 9/16 | 0.546 | 0.562 | 0.622 | 0.650 | 19/64 | 0.280 | 0.314 | 13/64 | 0.186 | 0.220 | 0.020 | 0.012 | 0.020 |

| 3/8 | 0.3750 | 11/16 | 0.669 | 0.688 | 0.763 | 0.794 | 23/64 | 0.341 | 0.377 | 15/64 | 0.216 | 0.252 | 0.021 | 0.014 | 0.021 |

| 7/16 | 0.4375 | 3/4 | 0.728 | 0.750 | 0.830 | 0.866 | 27/64 | 0.403 | 0.441 | 17/64 | 0.247 | 0.285 | 0.022 | 0.015 | 0.022 |

| 1/2 | 0.5000 | 7/8 | 0.850 | 0.875 | 0.969 | 1.010 | 31/64 | 0.464 | 0.504 | 19/64 | 0.277 | 0.317 | 0.023 | 0.016 | 0.023 |

| 9/16 | 0.5625 | 15/16 | 0.909 | 0.938 | 1.037 | 1.083 | 35/64 | 0.526 | 0.568 | 21/64 | 0.307 | 0.349 | 0.024 | 0.017 | 0.024 |

| 5/8 | 0.6250 | 1 1/16 | 1.031 | 1.062 | 1.175 | 1.227 | 39/64 | 0.587 | 0.631 | 23/64 | 0.337 | 0.381 | 0.025 | 0.018 | 0.025 |

| 3/4 | 0.7500 | 1 1/4 | 1.212 | 1.250 | 1.382 | 1.443 | 47/64 | 0.710 | 0.758 | 27/64 | 0.398 | 0.446 | 0.027 | 0.020 | 0.027 |

| 7/8 | 0.8750 | 1 7/16 | 1.394 | 1.438 | 1.589 | 1.660 | 55/64 | 0.833 | 0.885 | 31/64 | 0.458 | 0.510 | 0.029 | 0.022 | 0.029 |

| 1 | 1.0000 | 1 5/8 | 1.575 | 1.625 | 1.796 | 1.876 | 63/64 | 0.956 | 1.012 | 35/64 | 0.519 | 0.575 | 0.031 | 0.024 | 0.031 |

| 1 1/8 | 1.1250 | 1 13/16 | 1.756 | 1.812 | 2.002 | 2.093 | 1 7/64 | 1.079 | 1.139 | 39/64 | 0.579 | 0.639 | 0.033 | 0.027 | 0.033 |

| 1 1/4 | 1.2500 | 2 | 1.938 | 2.000 | 2.209 | 2.309 | 1 7/32 | 1.187 | 1.251 | 23/32 | 0.687 | 0.751 | 0.035 | 0.030 | 0.035 |

| 1 3/8 | 1.3750 | 2 3/16 | 2.119 | 2.188 | 2.416 | 2.526 | 1 11/32 | 1.310 | 1.378 | 25/32 | 0.747 | 0.815 | 0.038 | 0.033 | 0.038 |

| 1 1/2 | 1.5000 | 2 3/8 | 2.300 | 2.375 | 2.622 | 2.742 | 1 15/32 | 1.433 | 1.505 | 27/32 | 0.808 | 0.880 | 0.041 | 0.036 | 0.041 |

| 1 5/8 | 1.6250 | 2 9/16 | 2.481 | 2.562 | 2.828 | 2.959 | 1 19/32 | 1.556 | 1.632 | 29/32 | 0.868 | 0.944 | 0.044 | 0.038 | 0.044 |

| 1 3/4 | 1.7500 | 2 3/4 | 2.662 | 2.750 | 3.035 | 3.175 | 1 23/32 | 1.679 | 1.759 | 31/32 | 0.929 | 1.009 | 0.048 | 0.041 | 0.048 |

| 1 7/8 | 1.8750 | 2 15/16 | 2.844 | 2.938 | 3.242 | 3.392 | 1 27/32 | 1.802 | 1.886 | 1 1/32 | 0.989 | 1.073 | 0.051 | 0.044 | 0.051 |

| 2 | 2.0000 | 3 1/8 | 3.025 | 3.125 | 3.449 | 3.608 | 1 31/32 | 1.925 | 2.013 | 1 3/32 | 1.050 | 1.138 | 0.055 | 0.047 | 0.055 |

| 2 1/4 | 2.2500 | 3 1/2 | 3.388 | 3.500 | 3.862 | 4.041 | 2 13/64 | 2.155 | 2.251 | 1 13/64 | 1.155 | 1.251 | 0.061 | 0.052 | 0.061 |

| 2 1/2 | 2.5000 | 3 7/8 | 3.750 | 3.875 | 4.275 | 4.474 | 2 29/64 | 2.401 | 2.505 | 1 29/64 | 1.401 | 1.505 | 0.068 | 0.058 | 0.068 |

| 2 3/4 | 2.7500 | 4 1/4 | 4.112 | 4.250 | 4.688 | 4.907 | 2 45/64 | 2.647 | 2.759 | 1 37/64 | 1.522 | 1.634 | 0.074 | 0.064 | 0.074 |

| 3 | 3.0000 | 4 5/8 | 4.475 | 4.625 | 5.102 | 5.340 | 2 61/64 | 2.893 | 3.013 | 1 45/64 | 1.643 | 1.763 | 0.081 | 0.070 | 0.081 |

| 3 1/4 | 3.2500 | 5 | 4.838 | 5.000 | 5.515 | 5.774 | 3 3/16 | 3.124 | 3.252 | 1 13/16 | 1.748 | 1.876 | 0.087 | 0.075 | 0.087 |

| 3 1/2 | 3.5000 | 5 3/8 | 5.200 | 5.375 | 5.928 | 6.207 | 3 7/16 | 3.370 | 3.506 | 1 15/16 | 1.870 | 2.006 | 0.094 | 0.081 | 0.094 |

| 3 3/4 | 3.7500 | 5 3/4 | 5.562 | 5.750 | 6.341 | 6.640 | 3 11/16 | 3.616 | 3.760 | 2 1/16 | 1.990 | 2.134 | 0.100 | 0.087 | 0.100 |

| 4 | 4.0000 | 6 1/8 | 5.925 | 6.125 | 6.755 | 7.073 | 3 15/16 | 3.862 | 4.014 | 2 3/16 | 2.112 | 2.264 | 0.107 | 0.093 | 0.107 |

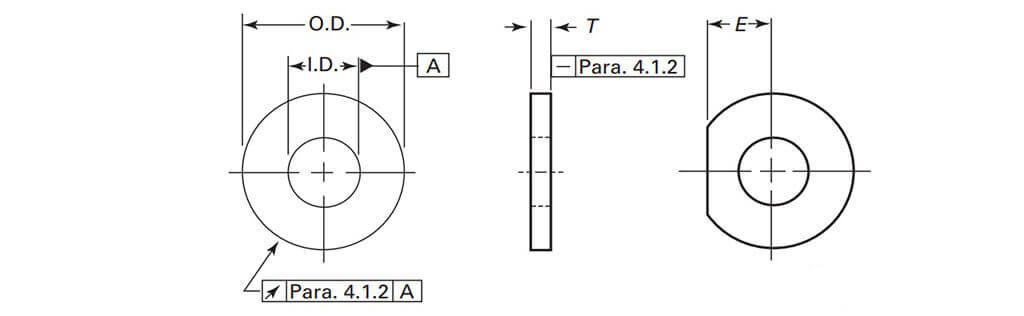

Zinc Plated Washer Dimensions Chart :

| Nominal Size | T | Clipped Width E, Min. | ||||||||||||

| I.D. | O.D. | Standard | Extra Thick | |||||||||||

| [Note (1)] | Max. | Min. | Max. | Min. | Max. | Min. | Max. | Min. | [Note (2)] | |||||

| 12 | 14.4 | 14 | 27 | 25.7 | 4.6 | 3.1 | 10 | 8 | 10.5 | |||||

| 16 | 18.4 | 18 | 34 | 32.4 | 4.6 | 3.1 | 10 | 8 | 14 | |||||

| 20 | 22.5 | 22 | 42 | 40.4 | 4.6 | 3.1 | 10 | 8 | 17.5 | |||||

| 22 | 24.5 | 24 | 44 | 42.4 | 4.6 | 3.4 | 10 | 8 | 19.2 | |||||

| 24 | 26.5 | 26 | 50 | 48.4 | 4.6 | 3.4 | 10 | 8 | 21 | |||||

| 27 | 30.5 | 30 | 56 | S4.1 | 4.6 | 3.4 | 10 | 8 | 23.6 | |||||

| 30 | 33.6 | 33 | 60 | 58.1 | 4.6 | 3.4 | 10 | 8 | 26.2 | |||||

| 36 | 39.6 | 39 | 72 | 70.1 | 4.6 | 3.4 | 10 | 8 | 31.S | |||||

| 42 | 45.6 | 45 | 84 | 81.8 | 7.2 | 4.6 | 10 | 8 | 36.7 | |||||

| 48 | 52.7 | 52 | 95 | 92.8 | 7.2 | 4.6 | 10 | 8 | 42 | |||||

| 56 | 62.7 | 62 | 107 | 104.8 | 8.7 | 6.1 | 10 | 8 | 49 | |||||

| 64 | 70.7 | 70 | 118 | 115.8 | 8.7 | 6.1 | 10 | 8 | 56 | |||||

| 72 | 78.7 | 78 | 130 | 127.5 | 8.7 | 6.1 | 10 | 8 | 63 | |||||

| 80 | 86.9 | 86 | 142 | 139.5 | 8.7 | 6.1 | 10 | 8 | 70 | |||||

| 90 | 96.9 | 96 | 159 | 156.5 | 8.7 | 6.1 | 10 | 8 | 78.7 | |||||

| 100 | 107.9 | 107 | 176 | 173.5 | 8.7 | 6.1 | 10 | 8 | 87.5 | |||||

Torque Chart Zinc Plated Fasteners

| Diameter (D) | Body Diameter (D) | Across the Flats (F) | Across the Corners © | Head Height (H) | Thread Lengths (T) | |||||

| MAX | MIN | MAX | MIN | MAX | MIN | MAX | MIN | <6” | >6” | |

| 1/2 | 0.515 | 0.482 | 0.875 | 0.85 | 1.01 | 0.969 | 0.364 | 0.302 | 1.25 | 1.5 |

| 5/8 | 0.642 | 0.605 | 1.062 | 1.031 | 1.227 | 1.175 | 0.444 | 0.378 | 1.5 | 1.75 |

| 3/4 | 0.768 | 0.729 | 1.25 | 1.212 | 1.443 | 1.383 | 0.524 | 0.455 | 1.75 | 2 |

| 7/8 | 0.895 | 0.852 | 1.438 | 1.394 | 1.66 | 1.589 | 0.604 | 0.531 | 2 | 2.25 |

| 1 | 1.022 | 0.976 | 1.625 | 1.575 | 1.876 | 1.796 | 0.7 | 0.591 | 2.25 | 2.5 |

| 1 1/8 | 1.149 | 1.098 | 1.812 | 1.756 | 2.093 | 2.002 | 0.78 | 0.658 | 2.5 | 2.75 |

| 1 1/4 | 1.277 | 1.223 | 2 | 1.938 | 2.309 | 2.209 | 0.876 | 0.749 | 2.75 | 3 |

| 1 3/8 | 1.404 | 1.345 | 2.188 | 2.119 | 2.526 | 2.416 | 0.94 | 0.81 | 3 | 3.25 |

| 1 1/2 | 1.531 | 1.47 | 2.375 | 2.3 | 2.742 | 2.622 | 1.036 | 0.902 | 3.25 | 3.5 |

| 1 3/4 | 1.785 | 1.716 | 2.75 | 2.662 | 3.175 | 3.035 | 1.196 | 1.054 | 3.75 | 4 |

| 2 | 2.039 | 1.964 | 3.125 | 3.025 | 3.608 | 3.449 | 1.388 | 1.175 | 4.25 | 4.5 |

| 2 1/4 | 2.305 | 2.214 | 3.5 | 3.388 | 4.041 | 3.862 | 1.548 | 1.327 | 4.75 | 5 |

| 2 1/2 | 2.559 | 2.461 | 3.875 | 3.75 | 4.474 | 4.275 | 1.708 | 1.479 | 5.25 | 5.5 |

| 2 3/4 | 2.827 | 2.711 | 4.25 | 4.112 | 4.907 | 4.688 | 1.869 | 1.632 | 5.75 | 6 |

| 3 | 3.081 | 2.961 | 4.625 | 4.475 | 5.34 | 5.102 | 2.06 | 1.815 | 6.25 | 6.5 |

Different Types Of Zinc Plated Fasteners

Different Types Of Fasteners

- Stainless Steel 304 Zinc Plated Fastener

- Stainless Steel 309 Zinc Plated Bolt

- UNS S30400 Zinc Plated Stud Bolt

- SS 316 Zinc Plated Fastener

- SS 316L Zinc Plated Fastener

- SS 347 Zinc Plated Fastener

- Stainless steel 310 Zinc Plated Fastener

- 309L Stainless Steel Zinc Plated Nuts

- ASTM A193 SS 304 Zinc Plated Washer

Application of Zinc Plated Fasteners

Testing of Zinc Plated Fasteners

Packing of Zinc Plated Fasteners

Destination Of Zinc Plated Fasteners

- City We Deliver

- Country We Export

- People Also Search