Nickel Alloy 200 Fasteners

High Nickel Alloys Fasteners

Nickel 200 Fasteners, UNS N02200 Hex Bolt, ASTM B160 Nickel 200 Stud Bolt, ASME SB160 Heavy Hex Nut, DIN 2.4066 Allen Bolt, Grade 200 Plain Washer, UNS N02200 Spring Washer.

Introduction of Nickel Alloy 200 fasteners:

Nickel Alloy 200 fasteners are employed to secure two parts temporarily together. The joint is constructed without causing any harm to exterior pieces, and removing it is likewise relatively simple. These fasteners create more durable non-permanent joins. It is employed in demanding situations where factories must keep the pressures at a minimum without leaks. Nickel 200, also known as UNS N02200, is wrought nickel that is economically pure and has excellent mechanical characteristics across a wide range of temperatures.

Properties of Nickel Alloy 200 fasteners:

Nickel 200 is a brand of wrought, pure commercial nickel with the alloy 200 classification. It resists a variety of harsh situations quite well and has excellent mechanical constants. Nickel Alloy 200 Hex Bolts possess several qualities that make them perfect for industrial applications, including low vapor pressure, high thermal conductivities, low gas content, and magnetic characteristics. It is resistant to harsh situations because of its good alloying element makeup. This grade can handle even the most potent chemicals and use organic and inorganic components.

This alloy has significant corrosion resistance in alkalis and acids in many practical reduction settings. This alloy has exceptional resistance to caustic alkalis, even in the molten form. This material has excellent resistance in alkaline, acidic, and neutral salt solutions but exhibits significant attack in oxidizing salt solutions. Additionally, the material is immune to dry vapors at ambient temperature and may be utilized with dry chlorine and chlorine gas at temperatures up to 550 degrees Celsius.

About Nickel Alloy 200 Fasteners

Benefits of Stainless Steel 321 Fasteners:

- Strong resistance to SCC in halide environments

- Strong resistance to pitting and crevice corrosion

- High yield strength and tensile strength

- Strong general resistance to corrosion

- High thermal conductivity and little thermal expansion

- Exceptional mechanical toughness

- A greater ability to withstand corrosive, erosive, and fatigue corrosion

Testing of Nickel Alloy 200 fasteners:

At highly functional production facility, the created variations of ASTM B160 Nickel 200 Stud Bolts are tested under the established quality checking requirements. The tests that are carried out include those for hardness, pitting resistance, flattening, flaring, mechanical, chemical, macro, and micro testing.

Applications of Nickel Alloy 200 fasteners:

DIN 2.4066 Heavy Hex Nuts are often used in ventilation systems, mechanical components, and other high-temperature equipment, as well as in pumps and actuator components, marine and salty devices, food production and serving equipment, and machinery susceptible to chemicals, solvents, and other corrosive materials. Other applications includes:

- Types of equipment used in the process of oil and gas extraction.

- Process equipment for the pharmaceutical industry

- Equipment for processing pulp and paper

Specification Of Nickel Alloy 200 Fasteners

| Specifications | ASME SB 160/ ASTM B 160 and DIN, ISO ,JIS ,GB, IS, BS, ASTM and all International Standards |

| Size | M3 - M100 | 3/6″ - 4″ | Custom Sizes |

| Fasteners Length | 3 mm - 200 mm | Custom Sizes |

| Nuts Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| Washers Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| Dimensions | DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3 |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads and UNF, BSW, BSF, METRIC, UNC, or as required |

| Form | Hex, Threading, Square, Round as per Gauge Etc. |

| Head | Hex, Square, Round, Hex flange, Flat, T-head & Triangular etc. |

| Neck type | Hex, Square, Triangular, Oval & Knurled etc. |

| Manufacturing Process | Passivation /plain, Wire Drawing, Cold Heading, Insert tapping, Heat Treatment, Surface Plating, Inspection, Packing. |

| Surface Coating | Black Oxide, Cadmium, Galvanized, Teflon, Xylan, Zinc, Others Upon Request |

| Packing | IN BULK: carton, pallet, Small Boxes or customer request |

| Test Certificate | As per EN 10204 / 3.1 Manufacturer Test Certificate, PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Delivery time | Regular product : 7-15 days, Custom product : 2-4 weeks |

Equivalent Grades Nickel Alloy 200 Fasteners

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Nickel 200 | 2.4066 | N02200 | NW 2200 | NA 11 | НП-2 | N-100M | Ni 99.2 |

Chemical Composition Nickel Alloy 200 Fasteners

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| Nickel 200 | 0.15 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

Mechanical Properties Nickel Alloy 200 Fasteners

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

Dimensions Of Nickel Alloy 200 Fasteners

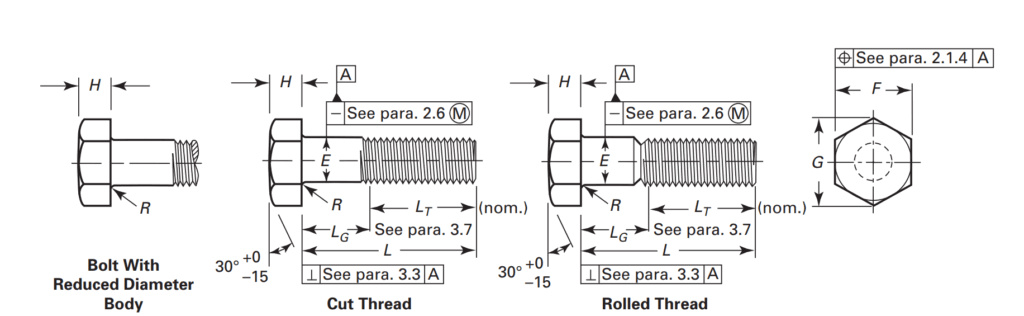

High Nickel Alloys Bolts Dimensions Chart :

| Nominal Size or Basic Product Diameter | Full-Size Body Diameter, E | Width Across Flats, F | Width Across Corners, G | Head Height, H Basic | Radius of Fillet, R | Nominal Thread Length for Bolt Lengths, LT |

|||||||||

| inch | mm | Max | Min | Basic inch | Max | Min | Max | Min | Basic inch | Max | Min | Max | Min | 6 in. and Shoter | Over 6 in. |

| 1⁄4 | 0.25 | 0.26 | 0.237 | 7⁄16 | 0.438 | 0.425 | 0.505 | 0.484 | 11⁄64 | 0.188 | 0.15 | 0.03 | 0.01 | 0.75 | 1 |

| 5⁄16 | 0.3125 | 0.324 | 0.298 | 1⁄2 | 0.5 | 0.484 | 0.577 | 0.552 | 7⁄32 | 0.235 | 0.195 | 0.03 | 0.01 | 0.875 | 1.125 |

| 3⁄8 | 0.375 | 0.388 | 0.36 | 9⁄16 | 0.562 | 0.544 | 0.65 | 0.62 | 1⁄4 | 0.268 | 0.226 | 0.03 | 0.01 | 1 | 1.25 |

| 7⁄16 | 0.4375 | 0.452 | 0.421 | 5⁄8 | 0.625 | 0.603 | 0.722 | 0.687 | 19⁄64 | 0.316 | 0.272 | 0.03 | 0.01 | 1.125 | 1.375 |

| 1⁄2 | 0.5 | 0.515 | 0.482 | 3⁄4 | 0.75 | 0.725 | 0.866 | 0.826 | 11⁄32 | 0.364 | 0.302 | 0.03 | 0.01 | 1.25 | 1.5 |

| 5⁄8 | 0.625 | 0.642 | 0.605 | 15⁄16 | 0.938 | 0.906 | 1.083 | 1.033 | 27⁄64 | 0.444 | 0.378 | 0.06 | 0.02 | 1.5 | 1.75 |

| 3⁄4 | 0.75 | 0.768 | 0.729 | 11⁄8 | 1.125 | 1.088 | 1.299 | 1.24 | 1⁄2 | 0.524 | 0.455 | 0.06 | 0.02 | 1.75 | 2 |

| 7⁄8 | 0.875 | 0.895 | 0.852 | 1 5⁄16 | 1.312 | 1.269 | 1.516 | 1.447 | 37⁄64 | 0.604 | 0.531 | 0.06 | 0.02 | 2 | 2.25 |

| 1 | 1 | 1.022 | 0.976 | 1 1⁄2 | 1.5 | 1.45 | 1.732 | 1.653 | 43⁄64 | 0.7 | 0.591 | 0.09 | 0.03 | 2.25 | 2.5 |

| 1 1⁄8 | 1.125 | 1.149 | 1.098 | 1 11⁄16 | 1.688 | 1.631 | 1.949 | 1.859 | 3⁄4 | 0.78 | 0.658 | 0.09 | 0.03 | 2.5 | 2.75 |

| 1 1⁄4 | 1.25 | 1.277 | 1.223 | 1 7⁄8 | 1.875 | 1.812 | 2.165 | 2.066 | 27⁄32 | 0.876 | 0.749 | 0.09 | 0.03 | 2.75 | 3 |

| 1 3⁄8 | 1.375 | 1.404 | 1.345 | 2 1⁄16 | 2.062 | 1.994 | 2.382 | 2.273 | 29⁄32 | 0.94 | 0.81 | 0.09 | 0.03 | 3 | 3.25 |

| 1 1⁄2 | 1.5 | 1.531 | 1.47 | 2 1⁄4 | 2.25 | 2.175 | 2.598 | 2.48 | 1 | 1.036 | 0.902 | 0.09 | 0.03 | 3.25 | 3.5 |

| 1 5⁄8 | 1.625 | 1.658 | 1.591 | 2 7⁄16 | 2.438 | 2.356 | 2.815 | 2.616 | 1 3⁄32 | 1.116 | 0.978 | 0.09 | 0.03 | 3.5 | 3.75 |

| 1 3⁄4 | 1.75 | 1.785 | 1.716 | 2 5⁄8 | 2.625 | 2.538 | 3.031 | 2.893 | 1 5⁄32 | 1.196 | 1.054 | 0.12 | 0.04 | 3.75 | 4 |

| 1 7⁄8 | 1.875 | 1.912 | 1.839 | 2 13⁄16 | 2.812 | 2.719 | 3.248 | 3.099 | 1 1⁄4 | 1.276 | 1.13 | 0.12 | 0.04 | 4 | 4.25 |

| 2 | 2 | 2.039 | 1.964 | 3 | 3 | 2.9 | 3.464 | 3.306 | 1 11⁄32 | 1.388 | 1.175 | 0.12 | 0.04 | 4.25 | 4.5 |

| 2 1⁄4 | 2.25 | 2.305 | 2.214 | 3 3⁄8 | 3.375 | 3.262 | 3.897 | 3.719 | 1 1⁄2 | 1.548 | 1.327 | 0.19 | 0.06 | 4.75 | 5 |

| 2 1⁄2 | 2.5 | 2.559 | 2.461 | 3 3⁄4 | 3.75 | 3.625 | 4.33 | 4.133 | 1 21⁄32 | 1.708 | 1.479 | 0.19 | 0.06 | 5.25 | 5.5 |

| 2 3⁄4 | 2.75 | 2.827 | 2.711 | 4 1⁄8 | 4.125 | 3.988 | 4.763 | 4.546 | 1 13⁄16 | 1.869 | 1.632 | 0.19 | 0.06 | 5.75 | 6 |

| 3 | 3 | 3.081 | 2.961 | 4 1⁄2 | 4.5 | 4.35 | 5.196 | 4.959 | 2 | 2.06 | 1.815 | 0.19 | 0.06 | 6.25 | 6.5 |

| 3 1⁄4 | 3.25 | 3.335 | 3.21 | 4 7⁄8 | 4.875 | 4.712 | 5.629 | 5.372 | 2 3⁄16 | 2.251 | 1.936 | 0.19 | 0.06 | 6.75 | 7 |

| 3 1⁄2 | 3.5 | 3.589 | 3.461 | 5 1⁄4 | 5.25 | 5.075 | 6.062 | 5.786 | 2 5⁄16 | 2.38 | 2.057 | 0.19 | 0.06 | 7.25 | 7.5 |

| 3 3⁄4 | 3.75 | 3.858 | 3.726 | 5 5⁄8 | 5.625 | 5.437 | 6.495 | 6.198 | 2 1⁄2 | 2.572 | 2.241 | 0.19 | 0.06 | 7.75 | 8 |

| 4 | 4 | 4.111 | 3.975 | 6 | 6 | 5.8 | 6.928 | 6.612 | 2 11⁄16 | 2.764 | 2.424 | 0.19 | 0.06 | 8.25 | 8.5 |

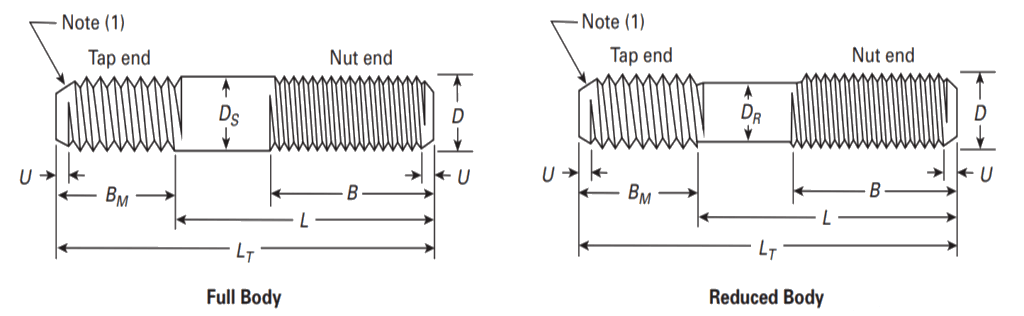

High Nickel Alloys Stud Bolts Dimensions Chart :

| Nominal Size Diameter, D inch | Tap End Full Thread Length, BM | Umax = 2P | Minimum Nut End Full Thread Length, Bmin |

||||||

| Nominal | Min. | Max. | UNC & NC-5 Thread | UNF Thread | 8UN Thread | L ≤ 10 | 10 | L > 16 | |

| 1/4 | 0.375 | 0.350 | 0.400 | 0.100 | 0.071 | ... | 0.750 | 1.000 | 1.500 |

| 5/16 | 0.469 | 0.440 | 0.498 | 0.111 | 0.083 | -- | 0.875 | 1.125 | 1.625 |

| 3/8 | 0.563 | 0.532 | 0.594 | 0.125 | 0.083 | -- | 1.000 | 1.250 | 1.750 |

| 7/16 | 0.656 | 0.620 | 0.692 | 0.143 | 0.100 | -- | 1.125 | 1.375 | 1.875 |

| 1/2 | 0.750 | 0.708 | 0.792 | 0.154 | 0.100 | -- | 1.250 | 1.500 | 2.000 |

| 9/16 | 0.844 | 0.802 | 0.896 | 0.167 | 0.111 | -- | 1.375 | 1.625 | 2.125 |

| 5/8 | 0.938 | 0.892 | 0.983 | 0.182 | 0.111 | -- | 1.500 | 1.750 | 2.250 |

| 3/4 | 1.1.25 | 1.075 | 1.175 | 0.200 | 0.125 | -- | 1.750 | 2.000 | 2.500 |

| 7/8 | 1.313 | 1.258 | 1.368 | 0.222 | 0.143 | -- | 2.000 | 2.250 | 2.750 |

| 1 | 1.500 | 1.438 | 1.562 | 0.250 | 0.167 | -- | 2.250 | 2.500 | 3.000 |

| 1 1/8 | 1.688 | 1.625 | 1.750 | 0.286 | 0.167 | 0.250 | 2.500 | 2.750 | 3.250 |

| 1 1/4 | 1.875 | 1.813 | 1.938 | 0.286 | 0.167 | 0.250 | 2.750 | 3.000 | 3.500 |

| 1 3/8 | 2.063 | 2.000 | 2.125 | 0.333 | 0.167 | 0.250 | 3.000 | 3.250 | 3.750 |

| 1 1/2 | 2.250 | 2.188 | 2.313 | 0.333 | 0.167 | 0.250 | 3.250 | 3.500 | 4.000 |

| 1 5/8 | 2.438 | 2.375 | 2.500 | -- | -- | 0.250 | 3.500 | 3.750 | 4.250 |

| 1 3/4 | 2.625 | 2.563 | 2.688 | 0.400 | -- | 0.250 | 3.750 | 4.000 | 4.500 |

| 1 7/8 | 2.813 | 2.750 | 2.875 | -- | -- | 0.250 | 4.000 | 4.250 | 4.750 |

| 2 | 3.000 | 2.925 | 3.075 | 0.444 | -- | 0.250 | 4.250 | 4.500 | 5.000 |

| 2 1/4 | 3.375 | 3.300 | 3.450 | 0.444 | -- | 0.250 | 4.750 | 5.000 | 5.500 |

| 2 1/2 | 3.750 | 3.675 | 3.825 | 0.500 | -- | 0.250 | 5.250 | 5.500 | 6.000 |

| 2 3/4 | 4.125 | 4.050 | 4.200 | 0.500 | -- | 0.250 | 5.750 | 6.000 | 6.500 |

| 3 | 4.500 | 4.425 | 4.575 | 0.500 | -- | 0.250 | -- | 6.500 | 7.000 |

| 3 1/4 | 4.875 | 4.775 | 4.975 | 0.500 | -- | 0.250 | -- | 7.000 | 7.500 |

| 3 1/2 | 5.250 | 5.150 | 5.350 | 0.500 | -- | 0.250 | -- | 7.500 | 8.000 |

| 3 3/4 | 5.625 | 5.525 | 5.725 | 0.500 | -- | 0.250 | -- | 8.000 | 8.500 |

| 4 | 6.000 | 5.900 | 6.100 | 0.500 | -- | 0.250 | -- | 8.500 | 9.000 |

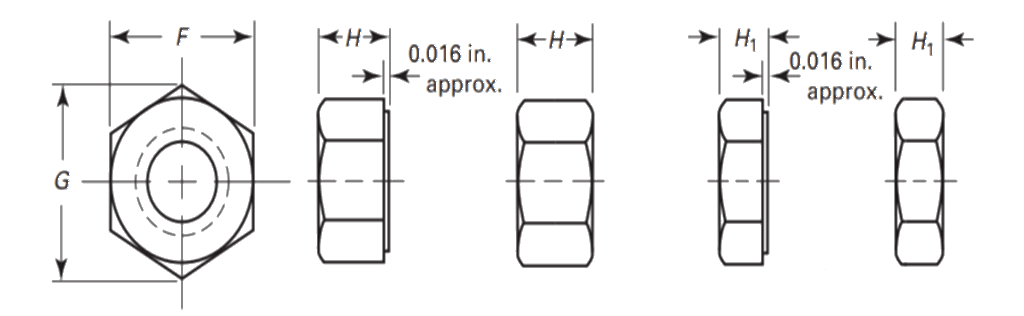

High Nickel Alloys Nuts Dimensions :

| Nominal Size inch | Basic Major Diameter of Thread | Width Across Flats, F | Width Across Corners, G | Thickness Heavy Hex Nuts, H | Thickness Heavy Hex Jam Nuts, H1 | Maximum Runout of Bearing Surface to Thread Axis, FIM |

|||||||||

| Heavy HEX NUTS | Heavy Hex Jam Nuts |

||||||||||||||

| Specified Proof load | |||||||||||||||

| Basic inch | Min. | Max | Min. | Max | Basic inch | Min. | Max | Basic inch | Min. | Max | Up to 150,000 psi | 150,000 psi and Greater | All Strength Levels |

||

| 1/4 | 0.2500 | 1/2 | 0.488 | 0.500 | 0.556 | 0.577 | 15/64 | 0.218 | 0.250 | 11/64 | 0.156 | 0.188 | 0.017 | 0.011 | 0.017 |

| 5/16 | 0.3125 | 9/16 | 0.546 | 0.562 | 0.622 | 0.650 | 19/64 | 0.280 | 0.314 | 13/64 | 0.186 | 0.220 | 0.020 | 0.012 | 0.020 |

| 3/8 | 0.3750 | 11/16 | 0.669 | 0.688 | 0.763 | 0.794 | 23/64 | 0.341 | 0.377 | 15/64 | 0.216 | 0.252 | 0.021 | 0.014 | 0.021 |

| 7/16 | 0.4375 | 3/4 | 0.728 | 0.750 | 0.830 | 0.866 | 27/64 | 0.403 | 0.441 | 17/64 | 0.247 | 0.285 | 0.022 | 0.015 | 0.022 |

| 1/2 | 0.5000 | 7/8 | 0.850 | 0.875 | 0.969 | 1.010 | 31/64 | 0.464 | 0.504 | 19/64 | 0.277 | 0.317 | 0.023 | 0.016 | 0.023 |

| 9/16 | 0.5625 | 15/16 | 0.909 | 0.938 | 1.037 | 1.083 | 35/64 | 0.526 | 0.568 | 21/64 | 0.307 | 0.349 | 0.024 | 0.017 | 0.024 |

| 5/8 | 0.6250 | 1 1/16 | 1.031 | 1.062 | 1.175 | 1.227 | 39/64 | 0.587 | 0.631 | 23/64 | 0.337 | 0.381 | 0.025 | 0.018 | 0.025 |

| 3/4 | 0.7500 | 1 1/4 | 1.212 | 1.250 | 1.382 | 1.443 | 47/64 | 0.710 | 0.758 | 27/64 | 0.398 | 0.446 | 0.027 | 0.020 | 0.027 |

| 7/8 | 0.8750 | 1 7/16 | 1.394 | 1.438 | 1.589 | 1.660 | 55/64 | 0.833 | 0.885 | 31/64 | 0.458 | 0.510 | 0.029 | 0.022 | 0.029 |

| 1 | 1.0000 | 1 5/8 | 1.575 | 1.625 | 1.796 | 1.876 | 63/64 | 0.956 | 1.012 | 35/64 | 0.519 | 0.575 | 0.031 | 0.024 | 0.031 |

| 1 1/8 | 1.1250 | 1 13/16 | 1.756 | 1.812 | 2.002 | 2.093 | 1 7/64 | 1.079 | 1.139 | 39/64 | 0.579 | 0.639 | 0.033 | 0.027 | 0.033 |

| 1 1/4 | 1.2500 | 2 | 1.938 | 2.000 | 2.209 | 2.309 | 1 7/32 | 1.187 | 1.251 | 23/32 | 0.687 | 0.751 | 0.035 | 0.030 | 0.035 |

| 1 3/8 | 1.3750 | 2 3/16 | 2.119 | 2.188 | 2.416 | 2.526 | 1 11/32 | 1.310 | 1.378 | 25/32 | 0.747 | 0.815 | 0.038 | 0.033 | 0.038 |

| 1 1/2 | 1.5000 | 2 3/8 | 2.300 | 2.375 | 2.622 | 2.742 | 1 15/32 | 1.433 | 1.505 | 27/32 | 0.808 | 0.880 | 0.041 | 0.036 | 0.041 |

| 1 5/8 | 1.6250 | 2 9/16 | 2.481 | 2.562 | 2.828 | 2.959 | 1 19/32 | 1.556 | 1.632 | 29/32 | 0.868 | 0.944 | 0.044 | 0.038 | 0.044 |

| 1 3/4 | 1.7500 | 2 3/4 | 2.662 | 2.750 | 3.035 | 3.175 | 1 23/32 | 1.679 | 1.759 | 31/32 | 0.929 | 1.009 | 0.048 | 0.041 | 0.048 |

| 1 7/8 | 1.8750 | 2 15/16 | 2.844 | 2.938 | 3.242 | 3.392 | 1 27/32 | 1.802 | 1.886 | 1 1/32 | 0.989 | 1.073 | 0.051 | 0.044 | 0.051 |

| 2 | 2.0000 | 3 1/8 | 3.025 | 3.125 | 3.449 | 3.608 | 1 31/32 | 1.925 | 2.013 | 1 3/32 | 1.050 | 1.138 | 0.055 | 0.047 | 0.055 |

| 2 1/4 | 2.2500 | 3 1/2 | 3.388 | 3.500 | 3.862 | 4.041 | 2 13/64 | 2.155 | 2.251 | 1 13/64 | 1.155 | 1.251 | 0.061 | 0.052 | 0.061 |

| 2 1/2 | 2.5000 | 3 7/8 | 3.750 | 3.875 | 4.275 | 4.474 | 2 29/64 | 2.401 | 2.505 | 1 29/64 | 1.401 | 1.505 | 0.068 | 0.058 | 0.068 |

| 2 3/4 | 2.7500 | 4 1/4 | 4.112 | 4.250 | 4.688 | 4.907 | 2 45/64 | 2.647 | 2.759 | 1 37/64 | 1.522 | 1.634 | 0.074 | 0.064 | 0.074 |

| 3 | 3.0000 | 4 5/8 | 4.475 | 4.625 | 5.102 | 5.340 | 2 61/64 | 2.893 | 3.013 | 1 45/64 | 1.643 | 1.763 | 0.081 | 0.070 | 0.081 |

| 3 1/4 | 3.2500 | 5 | 4.838 | 5.000 | 5.515 | 5.774 | 3 3/16 | 3.124 | 3.252 | 1 13/16 | 1.748 | 1.876 | 0.087 | 0.075 | 0.087 |

| 3 1/2 | 3.5000 | 5 3/8 | 5.200 | 5.375 | 5.928 | 6.207 | 3 7/16 | 3.370 | 3.506 | 1 15/16 | 1.870 | 2.006 | 0.094 | 0.081 | 0.094 |

| 3 3/4 | 3.7500 | 5 3/4 | 5.562 | 5.750 | 6.341 | 6.640 | 3 11/16 | 3.616 | 3.760 | 2 1/16 | 1.990 | 2.134 | 0.100 | 0.087 | 0.100 |

| 4 | 4.0000 | 6 1/8 | 5.925 | 6.125 | 6.755 | 7.073 | 3 15/16 | 3.862 | 4.014 | 2 3/16 | 2.112 | 2.264 | 0.107 | 0.093 | 0.107 |

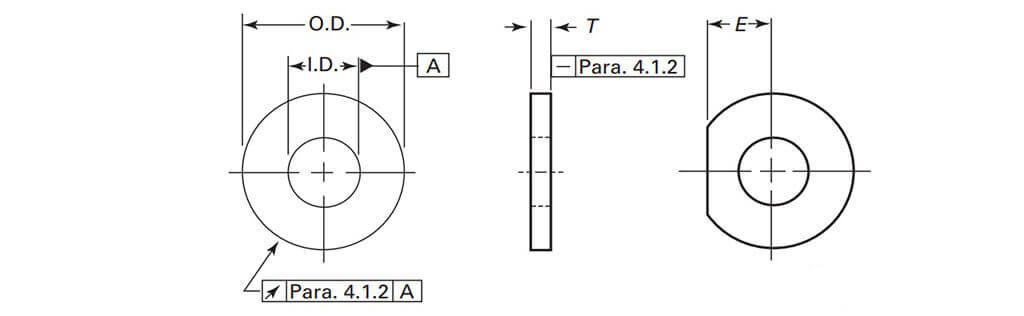

High Nickel Alloys Washer Dimensions Chart :

| Nominal Size | T | Clipped Width E, Min. | ||||||||||||

| I.D. | O.D. | Standard | Extra Thick | |||||||||||

| [Note (1)] | Max. | Min. | Max. | Min. | Max. | Min. | Max. | Min. | [Note (2)] | |||||

| 12 | 14.4 | 14 | 27 | 25.7 | 4.6 | 3.1 | 10 | 8 | 10.5 | |||||

| 16 | 18.4 | 18 | 34 | 32.4 | 4.6 | 3.1 | 10 | 8 | 14 | |||||

| 20 | 22.5 | 22 | 42 | 40.4 | 4.6 | 3.1 | 10 | 8 | 17.5 | |||||

| 22 | 24.5 | 24 | 44 | 42.4 | 4.6 | 3.4 | 10 | 8 | 19.2 | |||||

| 24 | 26.5 | 26 | 50 | 48.4 | 4.6 | 3.4 | 10 | 8 | 21 | |||||

| 27 | 30.5 | 30 | 56 | S4.1 | 4.6 | 3.4 | 10 | 8 | 23.6 | |||||

| 30 | 33.6 | 33 | 60 | 58.1 | 4.6 | 3.4 | 10 | 8 | 26.2 | |||||

| 36 | 39.6 | 39 | 72 | 70.1 | 4.6 | 3.4 | 10 | 8 | 31.S | |||||

| 42 | 45.6 | 45 | 84 | 81.8 | 7.2 | 4.6 | 10 | 8 | 36.7 | |||||

| 48 | 52.7 | 52 | 95 | 92.8 | 7.2 | 4.6 | 10 | 8 | 42 | |||||

| 56 | 62.7 | 62 | 107 | 104.8 | 8.7 | 6.1 | 10 | 8 | 49 | |||||

| 64 | 70.7 | 70 | 118 | 115.8 | 8.7 | 6.1 | 10 | 8 | 56 | |||||

| 72 | 78.7 | 78 | 130 | 127.5 | 8.7 | 6.1 | 10 | 8 | 63 | |||||

| 80 | 86.9 | 86 | 142 | 139.5 | 8.7 | 6.1 | 10 | 8 | 70 | |||||

| 90 | 96.9 | 96 | 159 | 156.5 | 8.7 | 6.1 | 10 | 8 | 78.7 | |||||

| 100 | 107.9 | 107 | 176 | 173.5 | 8.7 | 6.1 | 10 | 8 | 87.5 | |||||

Different Types Of Nickel Alloy 200 Fasteners

Different Types Of Bolts

- Nickel 200 Bolts

- DIN 2.4066 Carriage Bolts

- ASTM B160 Nickel 200 Hex Bolts

- Nickel 200 Forged Hook Bolts

- ASTM B160 UNS N02200 Eye Bolts

- Nickel 200 Allen Bolts

- Nickel Alloy 200 Flange Head Bolts

- 200 Nickel Hex Head Bolts

- 200 Nickel Torx Bolts

- UNS N02200 12-Point U Bolts

- Nickel 200 Countersunk Bolts

- A2-70 Nickel Bolts

Different Types Of Studs Bolts

- Nickel 200 Tap End Stud bolt

- UNS N02200 Continuous Threaded Stud bolt

- ASTM B160 Nickel 200 Double End Stud bolt

- ASME SB160 Nickel 200 Flange Stud bolt

- Werkstoff Nr. 2.4066 Fully Threaded Rod

- ASTM B160 UNS N02200 Stud Bolts

- A2-70 Nickel 200 Stud Bolts

- Grade 200 Half Threaded Rod

- 200 Nickel Stud Bolts

- Nickel 200 Hexagonal Stud bolts

- DIN 2.4066 Nickel 200 Threaded Stud bolts

Different Types Of Nuts

- Nickel 200 Metric Nuts

- 200 Nickel Sleeve Nuts

- DIN 2.4066 Captive Nuts

- ASTM B160 Nickel 200 Hex Nuts

- UNS N02200 Rivet Nuts

- ASME SB160 Acorn Nuts

- ASME SB160 Nickel 200 T Nuts

- Nickel Alloy 200 Dome Nuts

- ASTM B160 Grade 200 Lug Nut

- ASTM B160 UNS N02200 Castle Nuts

- Nickel 200 12-Point Nuts

- 200 Nickel Lock Nuts

Different Types Of Washer

- UNS N02200 Sealing Washer

- ASTM B160 Nickel 200 Plain Washer

- DIN 2.4066 Split Washer

- UNS N02200 Square Washer

- Nickel 200 Spring Washer

- Nickel Alloy 200 Star Washer

- Nickel 200 Spring Washer

- ASME SB160 Nickel 200 Tab Washer

- ASTM B160 Grade 200 Flat Washer

- 200 Nickel Lock Washer

Different Types Of Screw

- Nickel 200 Self Drilling Screws

- Nickel 200 Self Tapping Screws

- ASTM B160 Grade 200 Wood Screws

- DIN 2.4066 Grub Screws

- Grade 200 Polished Screws

- ASME SB160 Nickel 200 Countersunk Screws

- ASTM B160 Nickel 200 Torx Screws

- UNS N02200 Roofing Screws

Application of Nickel Alloy 200 Fasteners

Testing of Nickel Alloy 200 Fasteners

Packing of Nickel Alloy 200 Fasteners

Destination Of Nickel Alloy 200 Fasteners

- City We Deliver

- Country We Export

- People Also Search