Duplex UNS S31803 Fasteners

Home » Duplex UNS S31803 Fasteners

Duplex And Super Duplex Fasteners

Duplex S31803 Fasteners, ASTM A182 Duplex S31803 Stud Bolt, UNS S31803 Hex Bolt, ASME SA182 Heavy Hex Nut, DIN 1.4462 Allen Bolt, Grade S31803 Plain Washer, UNS S31803 Spring Washer.

What is meant by Duplex UNS S31803 Fasteners?

Standard, super, and lean duplexes are the three different types. The common duplex material is used to make the Duplex UNS S31803 Fasteners. The material’s composition includes nitrogen, 2.5% molybdenum, 4.5% nickel, 21% chromium, manganese, silicon, phosphorus, and carbon. There are several kinds, including hex bolts, threaded rods, screws, and nuts.

Properties of Duplex UNS S31803 Fasteners:

- The ferritic and austenitic properties of duplex steel combine to provide robust, corrosion-resistant fasteners.

- Additionally, the material has a minimum yield strength of 65 ksi and a minimum tensile strength of 90 ksi.

- The hardness of 2205 duplex steel bolts is 217HBW, and its elongation rate is 25%. They can also be employed in severe environments with a lot of wear and tear.

- These UNS S31803 Hex bolt alloys have a high yield strength and strong fatigue resistance. Therefore, this fastener selection exhibits ferritic and austenitic stainless steel properties.

- The fasteners exhibit exceptional resistance to pitting, stress corrosion cracking, and crevice corrosion in harsh environments. Additionally, they remarkably resist corrosion in situations with chloride and sulfuric acid.

- These Duplex Grade S31803 Threaded Bolts are machined either using high-speed or carbide tooling. Additionally, they are cold-worked using conventional techniques, and hot-working is done at temperatures between 954 and 1149 degrees Celsius.

- These fasteners are easily welded and exhibit slight intergranular corrosion after welding.

- It is a Duplex steel grade fastener that is ultra-low carbon duplex.

Previous

Next

About Duplex UNS S31803 Fasteners

Testing of Duplex UNS S31803 Fasteners:

Under the supervision of the test controllers, the items are rigorously checked and tested to ensure their quality and accuracy. These tests include the flare test, hardness test, pitting resistance test, mechanical test, PMI test, micro test, and macro test. The IGC test, radiography test, third-party inspection report, and ultrasonic test are further tests.

Applications of Duplex UNS S31803 Fasteners:

- ASTM A479 Duplex S31803 Stud bolts are utilized in various industries, including chemical processing, maritime, pulp and paper, transport, and storage. There are several kinds, including hex bolts, threaded rods, screws, and nuts.

- The hexagon-shaped head of the Duplex UNS S31803 Fasteners makes it easy to tighten or loosen with tools. These fasteners are typically utilized in engine parts and other densely packed components to minimize the amount of space the fasteners occupy.

- Duplex UNS S31803 Heavy Hex Nuts, renowned for their superb combination of solid corrosion resistance and superior mechanical qualities, are frequently employed in industrial applications, including manufacturing chemical containers for use in high-chloride settings and seawater heat exchangers.

Specification Of Duplex UNS S31803 Fasteners

| Specifications | ASTM A479, A182 / ASME SA479, SA182 and DIN, ISO ,JIS ,GB, IS, BS, ASTM and all International Standards |

| Size | M3 - M100 | 3/6″ - 4″ | Custom Sizes |

| Fasteners Length | 3 mm - 200 mm | Custom Sizes |

| Nuts Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| Washers Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| Dimensions | DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3 |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads and UNF, BSW, BSF, METRIC, UNC, or as required |

| Form | Hex, Threading, Square, Round as per Gauge Etc. |

| Head | Hex, Square, Round, Hex flange, Flat, T-head & Triangular etc. |

| Neck type | Hex, Square, Triangular, Oval & Knurled etc. |

| Manufacturing Process | Passivation /plain, Wire Drawing, Cold Heading, Insert tapping, Heat Treatment, Surface Plating, Inspection, Packing. |

| Surface Coating | Black Oxide, Cadmium, Galvanized, Teflon, Xylan, Zinc, Others Upon Request |

| Packing | IN BULK: carton, pallet, Small Boxes or customer request |

| Test Certificate | As per EN 10204 / 3.1 Manufacturer Test Certificate, PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Delivery time | Regular product : 7-15 days, Custom product : 2-4 weeks |

Equivalent Grades Duplex UNS S31803 Fasteners

| STANDARD | UNS | WNR. |

| Duplex Steel 31803 | S31803 | 1.4462 |

Chemical Composition Duplex UNS S31803 Fasteners

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| Duplex Steel S31803 | 0.030 max | 1.20 max | 0.80 max | 0.035 max | 0.020 max | 24.00 – 26.00 | 3.00 – 5.00 | 6.00 – 8.00 | 0.24 – 0.32 | 58.095 min |

Mechanical Properties Duplex UNS S31803 Fasteners

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.9 g/cm3 | 1402 °C (2555 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40 % |

Dimensions Of Duplex UNS S31803 Fasteners

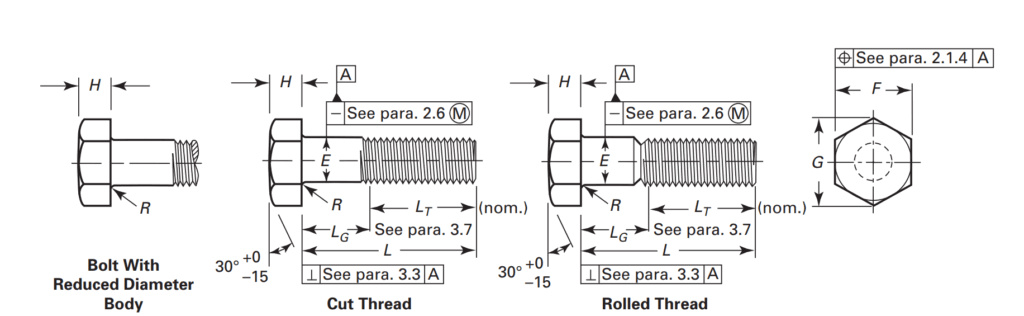

Duplex Steel Bolts Dimensions Chart :

| Nominal Size or Basic Product Diameter | Full-Size Body Diameter, E | Width Across Flats, F | Width Across Corners, G | Head Height, H Basic | Radius of Fillet, R | Nominal Thread Length for Bolt Lengths, LT |

|||||||||

| inch | mm | Max | Min | Basic inch | Max | Min | Max | Min | Basic inch | Max | Min | Max | Min | 6 in. and Shoter | Over 6 in. |

| 1⁄4 | 0.25 | 0.26 | 0.237 | 7⁄16 | 0.438 | 0.425 | 0.505 | 0.484 | 11⁄64 | 0.188 | 0.15 | 0.03 | 0.01 | 0.75 | 1 |

| 5⁄16 | 0.3125 | 0.324 | 0.298 | 1⁄2 | 0.5 | 0.484 | 0.577 | 0.552 | 7⁄32 | 0.235 | 0.195 | 0.03 | 0.01 | 0.875 | 1.125 |

| 3⁄8 | 0.375 | 0.388 | 0.36 | 9⁄16 | 0.562 | 0.544 | 0.65 | 0.62 | 1⁄4 | 0.268 | 0.226 | 0.03 | 0.01 | 1 | 1.25 |

| 7⁄16 | 0.4375 | 0.452 | 0.421 | 5⁄8 | 0.625 | 0.603 | 0.722 | 0.687 | 19⁄64 | 0.316 | 0.272 | 0.03 | 0.01 | 1.125 | 1.375 |

| 1⁄2 | 0.5 | 0.515 | 0.482 | 3⁄4 | 0.75 | 0.725 | 0.866 | 0.826 | 11⁄32 | 0.364 | 0.302 | 0.03 | 0.01 | 1.25 | 1.5 |

| 5⁄8 | 0.625 | 0.642 | 0.605 | 15⁄16 | 0.938 | 0.906 | 1.083 | 1.033 | 27⁄64 | 0.444 | 0.378 | 0.06 | 0.02 | 1.5 | 1.75 |

| 3⁄4 | 0.75 | 0.768 | 0.729 | 11⁄8 | 1.125 | 1.088 | 1.299 | 1.24 | 1⁄2 | 0.524 | 0.455 | 0.06 | 0.02 | 1.75 | 2 |

| 7⁄8 | 0.875 | 0.895 | 0.852 | 1 5⁄16 | 1.312 | 1.269 | 1.516 | 1.447 | 37⁄64 | 0.604 | 0.531 | 0.06 | 0.02 | 2 | 2.25 |

| 1 | 1 | 1.022 | 0.976 | 1 1⁄2 | 1.5 | 1.45 | 1.732 | 1.653 | 43⁄64 | 0.7 | 0.591 | 0.09 | 0.03 | 2.25 | 2.5 |

| 1 1⁄8 | 1.125 | 1.149 | 1.098 | 1 11⁄16 | 1.688 | 1.631 | 1.949 | 1.859 | 3⁄4 | 0.78 | 0.658 | 0.09 | 0.03 | 2.5 | 2.75 |

| 1 1⁄4 | 1.25 | 1.277 | 1.223 | 1 7⁄8 | 1.875 | 1.812 | 2.165 | 2.066 | 27⁄32 | 0.876 | 0.749 | 0.09 | 0.03 | 2.75 | 3 |

| 1 3⁄8 | 1.375 | 1.404 | 1.345 | 2 1⁄16 | 2.062 | 1.994 | 2.382 | 2.273 | 29⁄32 | 0.94 | 0.81 | 0.09 | 0.03 | 3 | 3.25 |

| 1 1⁄2 | 1.5 | 1.531 | 1.47 | 2 1⁄4 | 2.25 | 2.175 | 2.598 | 2.48 | 1 | 1.036 | 0.902 | 0.09 | 0.03 | 3.25 | 3.5 |

| 1 5⁄8 | 1.625 | 1.658 | 1.591 | 2 7⁄16 | 2.438 | 2.356 | 2.815 | 2.616 | 1 3⁄32 | 1.116 | 0.978 | 0.09 | 0.03 | 3.5 | 3.75 |

| 1 3⁄4 | 1.75 | 1.785 | 1.716 | 2 5⁄8 | 2.625 | 2.538 | 3.031 | 2.893 | 1 5⁄32 | 1.196 | 1.054 | 0.12 | 0.04 | 3.75 | 4 |

| 1 7⁄8 | 1.875 | 1.912 | 1.839 | 2 13⁄16 | 2.812 | 2.719 | 3.248 | 3.099 | 1 1⁄4 | 1.276 | 1.13 | 0.12 | 0.04 | 4 | 4.25 |

| 2 | 2 | 2.039 | 1.964 | 3 | 3 | 2.9 | 3.464 | 3.306 | 1 11⁄32 | 1.388 | 1.175 | 0.12 | 0.04 | 4.25 | 4.5 |

| 2 1⁄4 | 2.25 | 2.305 | 2.214 | 3 3⁄8 | 3.375 | 3.262 | 3.897 | 3.719 | 1 1⁄2 | 1.548 | 1.327 | 0.19 | 0.06 | 4.75 | 5 |

| 2 1⁄2 | 2.5 | 2.559 | 2.461 | 3 3⁄4 | 3.75 | 3.625 | 4.33 | 4.133 | 1 21⁄32 | 1.708 | 1.479 | 0.19 | 0.06 | 5.25 | 5.5 |

| 2 3⁄4 | 2.75 | 2.827 | 2.711 | 4 1⁄8 | 4.125 | 3.988 | 4.763 | 4.546 | 1 13⁄16 | 1.869 | 1.632 | 0.19 | 0.06 | 5.75 | 6 |

| 3 | 3 | 3.081 | 2.961 | 4 1⁄2 | 4.5 | 4.35 | 5.196 | 4.959 | 2 | 2.06 | 1.815 | 0.19 | 0.06 | 6.25 | 6.5 |

| 3 1⁄4 | 3.25 | 3.335 | 3.21 | 4 7⁄8 | 4.875 | 4.712 | 5.629 | 5.372 | 2 3⁄16 | 2.251 | 1.936 | 0.19 | 0.06 | 6.75 | 7 |

| 3 1⁄2 | 3.5 | 3.589 | 3.461 | 5 1⁄4 | 5.25 | 5.075 | 6.062 | 5.786 | 2 5⁄16 | 2.38 | 2.057 | 0.19 | 0.06 | 7.25 | 7.5 |

| 3 3⁄4 | 3.75 | 3.858 | 3.726 | 5 5⁄8 | 5.625 | 5.437 | 6.495 | 6.198 | 2 1⁄2 | 2.572 | 2.241 | 0.19 | 0.06 | 7.75 | 8 |

| 4 | 4 | 4.111 | 3.975 | 6 | 6 | 5.8 | 6.928 | 6.612 | 2 11⁄16 | 2.764 | 2.424 | 0.19 | 0.06 | 8.25 | 8.5 |

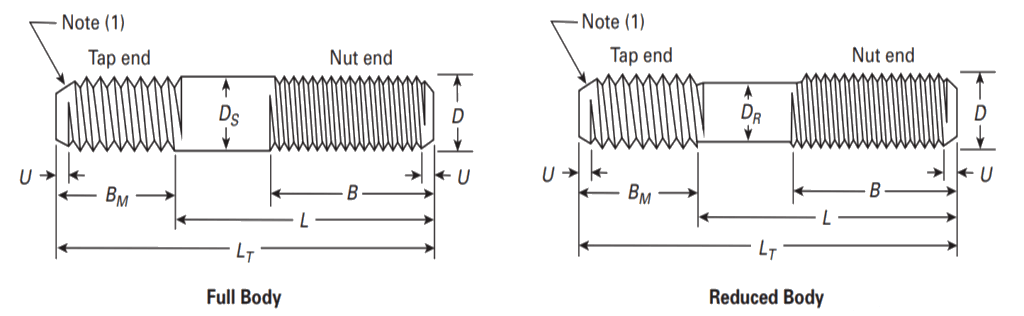

Duplex Steel Stud Bolts Dimensions Chart :

| Nominal Size Diameter, D inch | Tap End Full Thread Length, BM | Umax = 2P | Minimum Nut End Full Thread Length, Bmin |

||||||

| Nominal | Min. | Max. | UNC & NC-5 Thread | UNF Thread | 8UN Thread | L ≤ 10 | 10 | L > 16 | |

| 1/4 | 0.375 | 0.350 | 0.400 | 0.100 | 0.071 | ... | 0.750 | 1.000 | 1.500 |

| 5/16 | 0.469 | 0.440 | 0.498 | 0.111 | 0.083 | -- | 0.875 | 1.125 | 1.625 |

| 3/8 | 0.563 | 0.532 | 0.594 | 0.125 | 0.083 | -- | 1.000 | 1.250 | 1.750 |

| 7/16 | 0.656 | 0.620 | 0.692 | 0.143 | 0.100 | -- | 1.125 | 1.375 | 1.875 |

| 1/2 | 0.750 | 0.708 | 0.792 | 0.154 | 0.100 | -- | 1.250 | 1.500 | 2.000 |

| 9/16 | 0.844 | 0.802 | 0.896 | 0.167 | 0.111 | -- | 1.375 | 1.625 | 2.125 |

| 5/8 | 0.938 | 0.892 | 0.983 | 0.182 | 0.111 | -- | 1.500 | 1.750 | 2.250 |

| 3/4 | 1.1.25 | 1.075 | 1.175 | 0.200 | 0.125 | -- | 1.750 | 2.000 | 2.500 |

| 7/8 | 1.313 | 1.258 | 1.368 | 0.222 | 0.143 | -- | 2.000 | 2.250 | 2.750 |

| 1 | 1.500 | 1.438 | 1.562 | 0.250 | 0.167 | -- | 2.250 | 2.500 | 3.000 |

| 1 1/8 | 1.688 | 1.625 | 1.750 | 0.286 | 0.167 | 0.250 | 2.500 | 2.750 | 3.250 |

| 1 1/4 | 1.875 | 1.813 | 1.938 | 0.286 | 0.167 | 0.250 | 2.750 | 3.000 | 3.500 |

| 1 3/8 | 2.063 | 2.000 | 2.125 | 0.333 | 0.167 | 0.250 | 3.000 | 3.250 | 3.750 |

| 1 1/2 | 2.250 | 2.188 | 2.313 | 0.333 | 0.167 | 0.250 | 3.250 | 3.500 | 4.000 |

| 1 5/8 | 2.438 | 2.375 | 2.500 | -- | -- | 0.250 | 3.500 | 3.750 | 4.250 |

| 1 3/4 | 2.625 | 2.563 | 2.688 | 0.400 | -- | 0.250 | 3.750 | 4.000 | 4.500 |

| 1 7/8 | 2.813 | 2.750 | 2.875 | -- | -- | 0.250 | 4.000 | 4.250 | 4.750 |

| 2 | 3.000 | 2.925 | 3.075 | 0.444 | -- | 0.250 | 4.250 | 4.500 | 5.000 |

| 2 1/4 | 3.375 | 3.300 | 3.450 | 0.444 | -- | 0.250 | 4.750 | 5.000 | 5.500 |

| 2 1/2 | 3.750 | 3.675 | 3.825 | 0.500 | -- | 0.250 | 5.250 | 5.500 | 6.000 |

| 2 3/4 | 4.125 | 4.050 | 4.200 | 0.500 | -- | 0.250 | 5.750 | 6.000 | 6.500 |

| 3 | 4.500 | 4.425 | 4.575 | 0.500 | -- | 0.250 | -- | 6.500 | 7.000 |

| 3 1/4 | 4.875 | 4.775 | 4.975 | 0.500 | -- | 0.250 | -- | 7.000 | 7.500 |

| 3 1/2 | 5.250 | 5.150 | 5.350 | 0.500 | -- | 0.250 | -- | 7.500 | 8.000 |

| 3 3/4 | 5.625 | 5.525 | 5.725 | 0.500 | -- | 0.250 | -- | 8.000 | 8.500 |

| 4 | 6.000 | 5.900 | 6.100 | 0.500 | -- | 0.250 | -- | 8.500 | 9.000 |

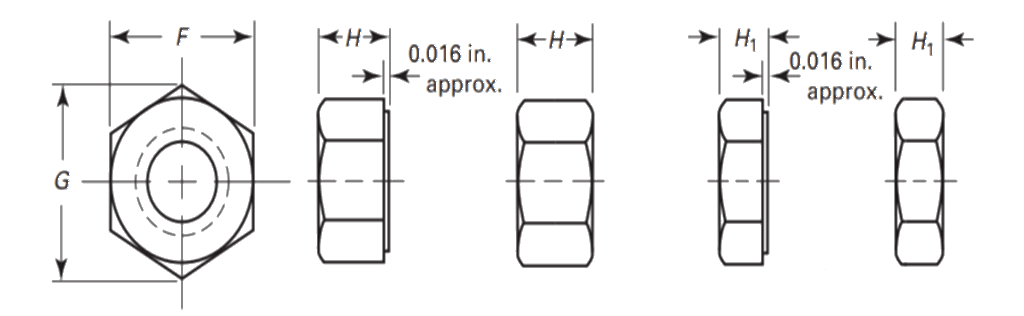

Duplex Steel Nuts Dimensions :

| Nominal Size inch | Basic Major Diameter of Thread | Width Across Flats, F | Width Across Corners, G | Thickness Heavy Hex Nuts, H | Thickness Heavy Hex Jam Nuts, H1 | Maximum Runout of Bearing Surface to Thread Axis, FIM |

|||||||||

| Heavy HEX NUTS | Heavy Hex Jam Nuts |

||||||||||||||

| Specified Proof load | |||||||||||||||

| Basic inch | Min. | Max | Min. | Max | Basic inch | Min. | Max | Basic inch | Min. | Max | Up to 150,000 psi | 150,000 psi and Greater | All Strength Levels |

||

| 1/4 | 0.2500 | 1/2 | 0.488 | 0.500 | 0.556 | 0.577 | 15/64 | 0.218 | 0.250 | 11/64 | 0.156 | 0.188 | 0.017 | 0.011 | 0.017 |

| 5/16 | 0.3125 | 9/16 | 0.546 | 0.562 | 0.622 | 0.650 | 19/64 | 0.280 | 0.314 | 13/64 | 0.186 | 0.220 | 0.020 | 0.012 | 0.020 |

| 3/8 | 0.3750 | 11/16 | 0.669 | 0.688 | 0.763 | 0.794 | 23/64 | 0.341 | 0.377 | 15/64 | 0.216 | 0.252 | 0.021 | 0.014 | 0.021 |

| 7/16 | 0.4375 | 3/4 | 0.728 | 0.750 | 0.830 | 0.866 | 27/64 | 0.403 | 0.441 | 17/64 | 0.247 | 0.285 | 0.022 | 0.015 | 0.022 |

| 1/2 | 0.5000 | 7/8 | 0.850 | 0.875 | 0.969 | 1.010 | 31/64 | 0.464 | 0.504 | 19/64 | 0.277 | 0.317 | 0.023 | 0.016 | 0.023 |

| 9/16 | 0.5625 | 15/16 | 0.909 | 0.938 | 1.037 | 1.083 | 35/64 | 0.526 | 0.568 | 21/64 | 0.307 | 0.349 | 0.024 | 0.017 | 0.024 |

| 5/8 | 0.6250 | 1 1/16 | 1.031 | 1.062 | 1.175 | 1.227 | 39/64 | 0.587 | 0.631 | 23/64 | 0.337 | 0.381 | 0.025 | 0.018 | 0.025 |

| 3/4 | 0.7500 | 1 1/4 | 1.212 | 1.250 | 1.382 | 1.443 | 47/64 | 0.710 | 0.758 | 27/64 | 0.398 | 0.446 | 0.027 | 0.020 | 0.027 |

| 7/8 | 0.8750 | 1 7/16 | 1.394 | 1.438 | 1.589 | 1.660 | 55/64 | 0.833 | 0.885 | 31/64 | 0.458 | 0.510 | 0.029 | 0.022 | 0.029 |

| 1 | 1.0000 | 1 5/8 | 1.575 | 1.625 | 1.796 | 1.876 | 63/64 | 0.956 | 1.012 | 35/64 | 0.519 | 0.575 | 0.031 | 0.024 | 0.031 |

| 1 1/8 | 1.1250 | 1 13/16 | 1.756 | 1.812 | 2.002 | 2.093 | 1 7/64 | 1.079 | 1.139 | 39/64 | 0.579 | 0.639 | 0.033 | 0.027 | 0.033 |

| 1 1/4 | 1.2500 | 2 | 1.938 | 2.000 | 2.209 | 2.309 | 1 7/32 | 1.187 | 1.251 | 23/32 | 0.687 | 0.751 | 0.035 | 0.030 | 0.035 |

| 1 3/8 | 1.3750 | 2 3/16 | 2.119 | 2.188 | 2.416 | 2.526 | 1 11/32 | 1.310 | 1.378 | 25/32 | 0.747 | 0.815 | 0.038 | 0.033 | 0.038 |

| 1 1/2 | 1.5000 | 2 3/8 | 2.300 | 2.375 | 2.622 | 2.742 | 1 15/32 | 1.433 | 1.505 | 27/32 | 0.808 | 0.880 | 0.041 | 0.036 | 0.041 |

| 1 5/8 | 1.6250 | 2 9/16 | 2.481 | 2.562 | 2.828 | 2.959 | 1 19/32 | 1.556 | 1.632 | 29/32 | 0.868 | 0.944 | 0.044 | 0.038 | 0.044 |

| 1 3/4 | 1.7500 | 2 3/4 | 2.662 | 2.750 | 3.035 | 3.175 | 1 23/32 | 1.679 | 1.759 | 31/32 | 0.929 | 1.009 | 0.048 | 0.041 | 0.048 |

| 1 7/8 | 1.8750 | 2 15/16 | 2.844 | 2.938 | 3.242 | 3.392 | 1 27/32 | 1.802 | 1.886 | 1 1/32 | 0.989 | 1.073 | 0.051 | 0.044 | 0.051 |

| 2 | 2.0000 | 3 1/8 | 3.025 | 3.125 | 3.449 | 3.608 | 1 31/32 | 1.925 | 2.013 | 1 3/32 | 1.050 | 1.138 | 0.055 | 0.047 | 0.055 |

| 2 1/4 | 2.2500 | 3 1/2 | 3.388 | 3.500 | 3.862 | 4.041 | 2 13/64 | 2.155 | 2.251 | 1 13/64 | 1.155 | 1.251 | 0.061 | 0.052 | 0.061 |

| 2 1/2 | 2.5000 | 3 7/8 | 3.750 | 3.875 | 4.275 | 4.474 | 2 29/64 | 2.401 | 2.505 | 1 29/64 | 1.401 | 1.505 | 0.068 | 0.058 | 0.068 |

| 2 3/4 | 2.7500 | 4 1/4 | 4.112 | 4.250 | 4.688 | 4.907 | 2 45/64 | 2.647 | 2.759 | 1 37/64 | 1.522 | 1.634 | 0.074 | 0.064 | 0.074 |

| 3 | 3.0000 | 4 5/8 | 4.475 | 4.625 | 5.102 | 5.340 | 2 61/64 | 2.893 | 3.013 | 1 45/64 | 1.643 | 1.763 | 0.081 | 0.070 | 0.081 |

| 3 1/4 | 3.2500 | 5 | 4.838 | 5.000 | 5.515 | 5.774 | 3 3/16 | 3.124 | 3.252 | 1 13/16 | 1.748 | 1.876 | 0.087 | 0.075 | 0.087 |

| 3 1/2 | 3.5000 | 5 3/8 | 5.200 | 5.375 | 5.928 | 6.207 | 3 7/16 | 3.370 | 3.506 | 1 15/16 | 1.870 | 2.006 | 0.094 | 0.081 | 0.094 |

| 3 3/4 | 3.7500 | 5 3/4 | 5.562 | 5.750 | 6.341 | 6.640 | 3 11/16 | 3.616 | 3.760 | 2 1/16 | 1.990 | 2.134 | 0.100 | 0.087 | 0.100 |

| 4 | 4.0000 | 6 1/8 | 5.925 | 6.125 | 6.755 | 7.073 | 3 15/16 | 3.862 | 4.014 | 2 3/16 | 2.112 | 2.264 | 0.107 | 0.093 | 0.107 |

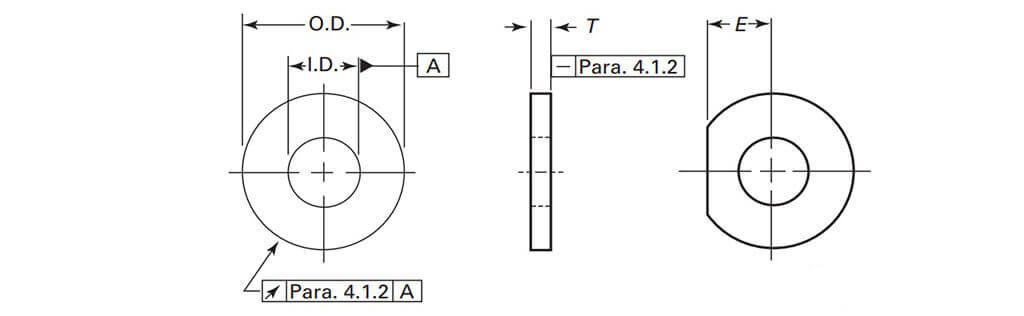

Duplex Steel Washer Dimensions Chart :

| Nominal Size | T | Clipped Width E, Min. | ||||||||||||

| I.D. | O.D. | Standard | Extra Thick | |||||||||||

| [Note (1)] | Max. | Min. | Max. | Min. | Max. | Min. | Max. | Min. | [Note (2)] | |||||

| 12 | 14.4 | 14 | 27 | 25.7 | 4.6 | 3.1 | 10 | 8 | 10.5 | |||||

| 16 | 18.4 | 18 | 34 | 32.4 | 4.6 | 3.1 | 10 | 8 | 14 | |||||

| 20 | 22.5 | 22 | 42 | 40.4 | 4.6 | 3.1 | 10 | 8 | 17.5 | |||||

| 22 | 24.5 | 24 | 44 | 42.4 | 4.6 | 3.4 | 10 | 8 | 19.2 | |||||

| 24 | 26.5 | 26 | 50 | 48.4 | 4.6 | 3.4 | 10 | 8 | 21 | |||||

| 27 | 30.5 | 30 | 56 | S4.1 | 4.6 | 3.4 | 10 | 8 | 23.6 | |||||

| 30 | 33.6 | 33 | 60 | 58.1 | 4.6 | 3.4 | 10 | 8 | 26.2 | |||||

| 36 | 39.6 | 39 | 72 | 70.1 | 4.6 | 3.4 | 10 | 8 | 31.S | |||||

| 42 | 45.6 | 45 | 84 | 81.8 | 7.2 | 4.6 | 10 | 8 | 36.7 | |||||

| 48 | 52.7 | 52 | 95 | 92.8 | 7.2 | 4.6 | 10 | 8 | 42 | |||||

| 56 | 62.7 | 62 | 107 | 104.8 | 8.7 | 6.1 | 10 | 8 | 49 | |||||

| 64 | 70.7 | 70 | 118 | 115.8 | 8.7 | 6.1 | 10 | 8 | 56 | |||||

| 72 | 78.7 | 78 | 130 | 127.5 | 8.7 | 6.1 | 10 | 8 | 63 | |||||

| 80 | 86.9 | 86 | 142 | 139.5 | 8.7 | 6.1 | 10 | 8 | 70 | |||||

| 90 | 96.9 | 96 | 159 | 156.5 | 8.7 | 6.1 | 10 | 8 | 78.7 | |||||

| 100 | 107.9 | 107 | 176 | 173.5 | 8.7 | 6.1 | 10 | 8 | 87.5 | |||||

Different Types Of Duplex UNS S31803 Fasteners

Different Types Of Bolts

- Duplex S31803 Bolts

- DIN 1.4462 Carriage Bolts

- ASTM A182 Duplex S31803 Hex Bolts

- Duplex S31803 Forged Hook Bolts

- ASTM A182 UNS S31803 Eye Bolts

- Duplex S31803 Allen Bolts

- Duplex S31803 Flange Head Bolts

- S31803 Duplex Hex Head Bolts

- S31803 Duplex Torx Bolts

- UNS S31803 12-Point U Bolts

- Duplex S31803 Countersunk Bolts

- A2-70 Duplex Bolts

Different Types Of Studs Bolts

- Duplex S31803 Tap End Stud bolt

- UNS S31803 Continuous Threaded Stud bolt

- ASTM A182 Duplex S31803 Double End Stud bolt

- ASME SA182 Duplex S31803 Flange Stud bolt

- Werkstoff Nr. 1.4462 Fully Threaded Rod

- ASTM A182 UNS S31803 Stud Bolts

- A2-70 Duplex S31803 Stud Bolts

- Grade S31803 Half Threaded Rod

- S31803 Duplex Stud Bolts

- Duplex S31803 Hexagonal Stud bolts

- DIN 1.4462 Duplex S31803 Threaded Stud bolts

Different Types Of Nuts

- Duplex S31803 Metric Nuts

- S31803 Duplex Sleeve Nuts

- DIN 1.4462 Captive Nuts

- ASTM A182 Duplex S31803 Hex Nuts

- UNS S31803 Rivet Nuts

- ASME SA182 Acorn Nuts

- ASME SA182 Duplex S31803 T Nuts

- Duplex S31803 Dome Nuts

- ASTM A182 Grade S31803 Lug Nut

- ASTM A182 UNS S31803 Castle Nuts

- Duplex S31803 12-Point Nuts

- S31803 Duplex Lock Nuts

Different Types Of Washer

- UNS S31803 Sealing Washer

- ASTM A182 Duplex S31803 Plain Washer

- DIN 1.4462 Split Washer

- UNS S31803 Square Washer

- Duplex S31803 Spring Washer

- Duplex S31803 Star Washer

- Duplex S31803 Spring Washer

- ASME SA182 Duplex S31803 Tab Washer

- ASTM A182 Grade S31803 Flat Washer

- S31803 Duplex Lock Washer

Different Types Of Screw

- Duplex S31803 Self Drilling Screws

- Duplex S31803 Self Tapping Screws

- ASTM A182 Grade S31803 Wood Screws

- DIN 1.4462 Grub Screws

- Grade S31803 Polished Screws

- ASME SA182 Duplex S31803 Countersunk Screws

- ASTM A182 Duplex S31803 Torx Screws

- UNS S31803 Roofing Screws

Application of Duplex UNS S31803 Fasteners

Construction

Bridges

Engineering

General Structural Purposes

Petrochemical Industry

Ship Building

Previous

Next

Testing of Duplex UNS S31803 Fasteners

Chemical Analysis

Deimension

Fasteners-testings

Flaring Test

Hardness Test

nondestructive-testing

Previous

Next

Packing of Duplex UNS S31803 Fasteners

Wrapping Machine Steel pipe

Wooden Boxes

seamless pipe Packing

Packing Systems

Machine Fasteners Packaging

Fasteners Packaging

Previous

Next

Destination Of Duplex UNS S31803 Fasteners

- City We Deliver

- Country We Export

- People Also Search

Duplex S31803 Allen Bolt Exporter in Pune, Duplex S31803 Lag Bolt Manufacturer in Hyderabad, ASTM A479 Duplex S31803 Hex Bolt Manufacturer in Bengaluru, Duplex S31803 Square Bolt Stockist in Dammam, Duplex S31803 Stud Bolt Stockist in Pimpri-Chinchwad, Din 1.4462 Head Hex Nut Stockist in Bangalore, ASME SA479 Duplex S31803 Industrial Fasteners Exporter in Nashik, UNS S31803 Hot Forged Bolts Supplier in Vadodara, ASTM A479 Duplex S31803 high tensile Bolts Manufacturer in Bharuch, Din 1.4462 Hex nut Exporter in Hyderabad, Din 1.4462 Carriage Bolt Exporter in Dubai, Duplex S31803 Steel Bolt Supplier in Coimbatore, ASME SA479 Duplex S31803 Spring washer Stockist in Ahmedabad, ASTM A479 Duplex S31803 Heavy Hex Bolt Supplier in Chennai, Duplex S31803 U Bolt Supplier in Abu Dhabi, UNS S31803 Plain Washer Manufacturer in Mumbai.

UNS S31803 Hot Forged Bolts Supplier in Vietnam, ASME SA479 Duplex S31803 Industrial Fasteners Exporter in Oman, Duplex S31803 Stud Bolt Stockist in UK, Duplex S31803 Lag Bolt Manufacturer in Indonesia, Din 1.4462 Head Hex Nut Stockist in South Africa, Din 1.4462 Hex nut Exporter in Kuwait, Duplex S31803 U Bolt Supplier in UK, Duplex S31803 Allen Bolt Exporter in Qatar, UNS S31803 Plain Washer Manufacturer in Singapore, Duplex S31803 Square Bolt Stockist in Italy, ASTM A479 Duplex S31803 Heavy Hex Bolt Supplier in UAE, ASTM A479 Duplex S31803 high tensile Bolts Manufacturer in Australia, ASTM A479 Duplex S31803 Hex Bolt Manufacturer in USA, Duplex S31803 Steel Bolt Supplier in Saudi Arabia, ASME SA479 Duplex S31803 Spring washer Stockist in Malaysia, Din 1.4462 Carriage Bolt Exporter in Canada.

Get UNS S31803 Head Hex Nut Chemical Composition, A wide range of Duplex S31803 Fasteners Size Chart, Duplex S31803 Grade Fastener Price Per Kg, Din 1.4462 Hex Bolt Weight Calculator, Buy Duplex S31803 Stud bolts, Best Quality of S31803 Grade Bolts, ASTM A479 Duplex S31803 Weight Chart, UNS S32205 Duplex Fasteners Price List In India, Austenitic S31803 Duplex Nuts, Duplex S31803 Heavy Hex Bolt Dimension PDF, Duplex S31803 Anchor Bolt Price List, ASME SA479 Duplex S31803 Square Bolt Catalogue, Get Quote Now of S31803 Fasteners At Factory Price.